IWC Manufacturing Center, Schaffhausen Building Development, Swiss Commercial Architecture Photos

IWC Manufacturing Center Schaffhausen

5 Feb 2020

IWC Manufacturing Center

Design: ATP architects engineers

Location: Schaffhausen, Switzerland

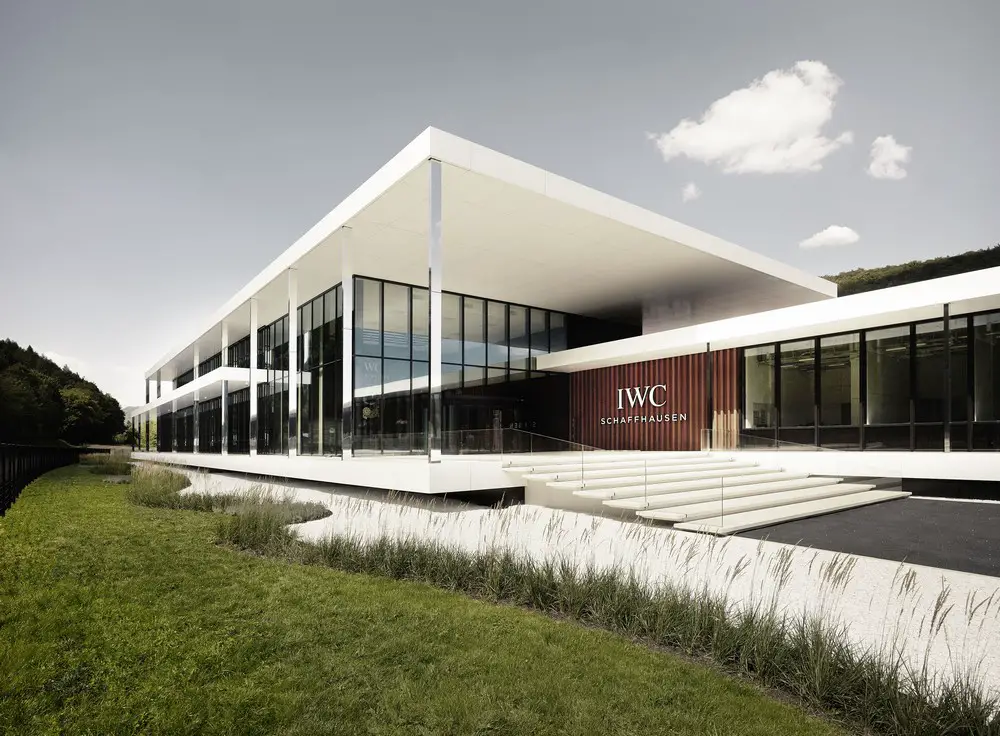

The design of the IWC Manufacturing Center in Schaffhausen by ATP architects engineers (Zurich) slips harmoniously into the landscape and recalls the pavilion-like buildings of the Modern Movement. The new facility not only improves the production process by bringing together the manufacturing of components, movements and cases in a single location. Visitors to the Manufacturing Center can also experience how IWC’s luxury watches are created at close hand.

“All our core processes and the steps in the manufacturing operation that occurred at various sites have now been brought together under this one roof,” explained Andreas Voll, Chief Operating Officer of IWC, to mark the opening of the plant at the end of August 2018. The manufacturer of luxury watches has equipped the new building with optimized production logistics that include the entire casing and component manufacturing processes and the assembly of movements.

History

Ever since the American Florentine Ariosto Jones established the International Watch Company in Schaffhausen in 1868, IWC and the Swiss town have been inextricably linked. The pioneering American watchmaker put his faith in both the craftsmanship of the Swiss watchmakers and modern technology while also making full use of the energy offered by the waters of the River Rhine. In 1874/75 IWC built a factory that has served as its headquarters until today.

The building in the historic center of Schaffhausen was extended in 2005 and 2008. Despite this, however, the capacity of the headquarters had been reached and the company decided to create a new Manufacturing Center just eight kilometers away in Merishausertal. The new building represents the third expansion in 13 years and symbolizes both 150 years of craftsmanship and the continuous growth of the traditional company.

IWC found an ideal partner in ATP architects engineers (Zurich) for the construction of this new Manufacturing Center, which also introduces visitors to the world of IWC. For ATP is not only a specialist for integrated design, in which architectural and engineering services go hand in hand, but is also unequalled in its uncompromising commitment to the needs of its clients, which was a key demand of IWC.

“We wanted to build a building that aptly expresses the spirit of our company,” said the CEO of IWC Schaffhausen Christoph Grainger-Herr, himself an architect, on the occasion of the opening.

Just as IWC combines craftsmanship and technical innovation in order to manufacture premium watches, the new Manufacturing Center can also be read as a combination of constructional craftsmanship and innovation.

Concept

The project by ATP architects engineers is fundamentally influenced by the pavilion-like buildings of the Modern Movement. The designers were similarly inspired by the elegant precision objects manufactured by IWC.

“The building appears as discreet, filigree and contemporary as an IWC Portuguese Watch” emphasized Jürgen Zipf, the Lead Project Manager of ATP Zurich, who was responsible for the new building. Hence, rather than a standard production plant this is an exquisite manufacturing operation.

The workstations are located in large, light-filled halls. These spacious production areas simplify cooperation and can also be flexibly adapted for the future challenges of the manufacturing process.

“In this respect the building also meets the requirements and wishes of IWC. Every day it could be used in a different way – with minimal extra effort,” reports Zipf.

The spatial context also played a significant role in the design of the building. “Local features such as the forest and the river influenced our planning. And we also played with the slope on the site,” explained Zipf.

The new IWC Manufacturing Center stands self-confidently on a slight rise at the end of the small industrial area in Merishausertal, which is surrounded by forests. The new two-story building neither arrogantly dominates the hill nor diffidently retreats into the slope. Rather, it subtly refers to the topography of the valley by taking the form of a visible architectural symbol, which nestles against the rising ground. A generous roof terrace in front of the second floor canteen offers particularly impressive views of the delightful valley.

Spatial program

In the future up to 400 employees will be able to work in the spatially flexible production halls. This flexibility is based on a continuous constructional grid of 13.5 x 13.5 meters in the large production areas that are available for the positioning of furniture and machinery and can be flexibly divided. Secondary beams at centers of 2.25 meters repeatedly coincide with the main 1.50 meter grid.

The spatial sequence of the 139-meter-long building accompanies the production processes and the varying requirements of the individual working steps – from the open production areas to the special spaces for chemical galvanizing processes and quality assurance to the clean room.

Media columns almost invisibly bring together a range of connections and installations – in a uniform and optically sophisticated solution. The upper level is home to the canteen and roof terrace. In addition to all this, this is a place in which visitors can see the know-how that combines high technology with traditional craftsmanship. They can experience the manufacturing facility as a showroom, in which they are able to follow all production processes.

Façade

The designers integrated the corporate design of the luxury watch manufacturers into the language of the building envelope. The precision employed in producing watches is reflected in the precise assembly of the façade. This also knowingly incorporates part of the air intake system. The façade and the interior finishes were consistently designed and built in line with the grid of 1.50 x 1.50 meters.

The post-and-rail façade has closed window breasts. White Alucobond panels delineate the cantilevers that are responsible for the pavilion-like character. These alternate with closed, black surfaces. Full-height external blinds which also cover the solid window breasts provide the necessary shade. The cantilevered, filigree canopy has a free span of over three meters. Non-load-bearing stainless steel uprights enhance the elegant structure. The façade is triple-glazed.

Interior

Visitors already get a sense of luxury at the entrée. A wide, imposing open-air concrete stair below a cantilevered canopy measuring nine-meters draws them upwards, accompanied by special effect lighting at night. The staircase elements consist of blocks measuring 13 x 1.20 meters which were manufactured in a single pour.

The fixings of the glass balustrade are invisible. The slender overhang indicates the route into the building where selected, refined materials and colors combine to create an elegant entrance hall. An over-dimensional precision watch movement dominates the reception desk like a work of art. Inside the building glazed partitions guarantee transparency. But visitors also encounter solid concrete cores.

A specially designed timber wall reinforced by metal suspended ceilings above the main circulation routes act as a guide for visitors. The colors – black and white – and the contrast between them dominate the interior spaces. Light-gray floors, black-stained concrete walls and finely-grained timber paneling with a hint of red enhance the elegant range of materials.

The lighting is also integrated into the building grid in the form of square LED lights, which cover the entire production area in a checkerboard pattern. These deliver up to 900 lux to the working surfaces from a height of five meters. The entire ventilation system is also integrated into this square grid.

Exterior

In the refined external areas to the west of the building well-tended lawns guarantee uninterrupted views of the elegant building. These are framed by fields of reeds and lavender. White Carrara marble gravel marks the transition from these open spaces to the building. Special structural elements and a well-thought-through lighting concept underline the special character of this zone. The concrete elements were produced specially and are color-coordinated with the interior design of the lobby.

The employee car park to the east is composed of grass pavers. Asymmetrically planted hornbeam hedges break up this open space. To the north and south of the building the well-tended lawns merge into colorful meadows. The arrays of hedges to the northern and southern boundaries will act in the future as corridors in which the local bat population can move freely. The planting of these hedges was a statutory requirement of the building permit.

The ancillary buildings are constructed of fair-faced concrete with a black stain. The anthracite black surfaces are aligned with the new building.

Building services

The desire for a building characterized by precise elegance is reflected by the fact that the complex technical plant on the roof is more-or-less invisible. Large areas of this roof are covered by photovoltaic plant, which provides much of the energy required by the building.

In addition to this, the high energy demand is also met by an air and water-based heat recovery system and the use of the groundwater for cooling and heating. All thermal insulation measures are based on the Minergy Standard. The experience of a planning office which practices integrated design is particularly valuable when addressing the complex requirements in the areas of energy efficiency, sustainability and lifecycle orientation.

The groundwater is used to heat and cool the building. All rainwater collected on the roof is directed to retention surfaces with the excess flowing into the Durach stream. Rather than being directed into the drains the rainwater falling onto the areas surrounding the building is allowed to seep away via the hard shoulder. The building has an intelligent waste and recycling management system conceived to ensure the reprocessing of production waste.

Digital design

The IWC Manufacturing Center was designed by ATP Zurich with the help of a detailed digital building model with BIM (Building Information Modeling). This method creates buildings using this digital building model, which is complete down to the last detail and stores all relevant information in a database. This digital twin is added to by all participants throughout the entire design process in order to be able to ensure the optimal design, execution and, eventually, operation of the building.

ATP architects engineers is an innovation leader in the field of Building Information Modeling (BIM). BIM has been used throughout ATP to design buildings since 2012. Integrated design by ATP can make comprehensive use of the advantages of BIM. The BIM Standard, which was developed by ATP over the course of a number of years, contributed to the Austrian BIM Norm (ÖNORM A 6241). ATP has placed it at the disposition of all market participants via the BIMpedia knowledge platform.

A total of 25 engineering and design offices, more than 70 construction companies and over 1,000 craftspeople made a contribution to the success of the project. 8,400 cubic meters of concrete together with more than 1,000 tons of reinforcing steel and 3,300 square meters of glass were incorporated into the 13,500 square meters of production space. The floor plate, load-bearing walls and stair cores are built of fair-faced concrete and the main load-bearing frame is formed of steel while the slabs are composite steel structures.

IWC Manufacturing Center, Switzerland – Building Information

Client: IWC Schaffhausen, Branch of Richemont International SA

Location: Schaffhausen, CH

Integrated design: ATP architects engineers (Zurich)

Lead project manager: Jürgen Zipf

Construction start: 02/2016

Completion: 11/2017

Opening: 08/2018

Gross floor area: 13,500 m2

Gross built volume: 75,000 m3

Integrated design: ATP architects engineers (Zurich)

Construction start: 02/2016

Completion: 11/2017

Opening: 08/2018

Photography © ATP/Jantscher and IWC

ATP architects engineers – Austria, Germany

IWC Manufacturing Center, Schaffhausen, CH images / information received 050220

Location: Schaffhausen, Switzerland

Architecture in Switzerland

Swiss Architecture Designs – chronological list

Swiss Architecture Walking Tours

Recent buildings by ATP architects engineers on e-architect

Industrial Kitchen, 23rd district, Vienna, Austria

photography : ATP/Becker

magdas Industrial Kitchen in Vienna

Markas Headquarters, Northwest Italy

Design: ATP Architects Engineers

photography : ATP/Becker

Markas Headquarters in Bolzano

Allianz Headquarters in Zürich – building news

Design: Wiel Arets Architects

Allianz Headquarters Zürich

Allianz HQ Zürich : background information

Comments / photos for this IWC Manufacturing Center in Schaffhausen, Switzerland page welcome