Reciprocating Air Compressors guide, AC parts filter cleaning, Electric or gas power types, Ventilation exhaust

Reciprocating Air Compressors: A Buyer’s Guide from a Trusted Supplier

May 21, 2025

For many individuals and businesses seeking a reliable source of compressed air, the reciprocating air compressor stands out as a durable and versatile option. As a leading air compressor supplier, we understand that choosing the right compressor can be a significant decision. This comprehensive buyer’s guide aims to demystify the world of reciprocating compressors, providing you with the essential knowledge to make an informed purchase that aligns with your specific needs and applications. We’ll explore the core technology, different types available, key factors to consider, and ultimately, how to select the ideal reciprocating compressor for your tasks.

The Enduring Appeal of Reciprocating Technology: How It Works

At its heart, a reciprocating air compressor utilizes pistons moving back and forth within cylinders to compress air. This fundamental design, similar to that of an internal combustion engine, has proven to be robust and efficient for a wide range of applications. As the piston moves down, it creates a vacuum, drawing air into the cylinder through an intake valve. As the piston moves up, it compresses the air, forcing it out through a discharge valve and into the storage tank. This cyclical process continues to build pressure within the tank until the desired level is reached.

Understanding Single-Stage vs. Two-Stage Compressors: Matching Power to Demand

A primary distinction among reciprocating compressors lies in whether they are single-stage or two-stage units. This difference in design significantly impacts the pressure they can generate and their overall efficiency.

Single-Stage Compressors: Ideal for Intermittent and Lower-Pressure Needs

Single-stage compressors compress air in a single pass within the cylinder, typically reaching maximum pressures of around 125-150 PSI. These units are generally more affordable, lighter, and suitable for a wide array of intermittent tasks and applications that don’t require extremely high pressure, such as powering nail guns, airbrushes, and inflation tools. They are a popular choice for home users and smaller workshops.

Two-Stage Compressors: Delivering Higher Pressure and Efficiency for Continuous Use

Two-stage compressors, on the other hand, compress air in two steps. The air is first compressed in a larger cylinder and then transferred to a smaller cylinder for further compression, achieving significantly higher pressures, often ranging from 175 PSI or more. This two-stage process also results in greater efficiency and cooler operating temperatures, making them better suited for continuous use and powering more demanding air tools like impact wrenches, grinders, and paint sprayers in professional settings.

Oil-Lubricated vs. Oil-Free Reciprocating Compressors: Considering Maintenance and Air Quality

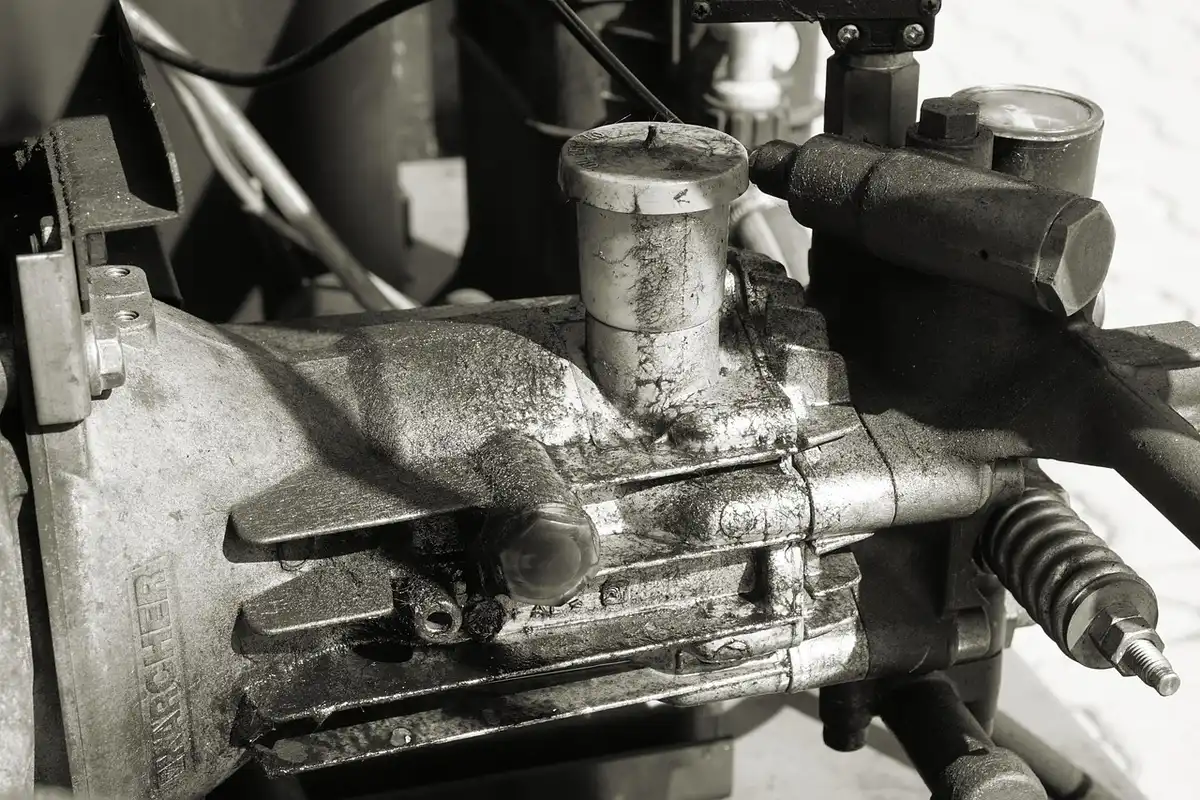

Oil-Lubricated Compressors: Robust Performance and Longevity

Oil-lubricated reciprocating compressors utilize oil to lubricate the moving parts within the pump, reducing friction and wear. These units are generally known for their robust performance, long lifespan, and ability to handle demanding tasks. However, they require regular oil level checks and periodic oil changes, adding to the maintenance requirements. There is also a potential for oil carry-over into the compressed air, which may not be suitable for certain sensitive applications like painting or medical use without additional filtration.

Oil-Free Compressors: Low Maintenance and Cleaner Air

Oil-free reciprocating compressors utilize permanently lubricated components or specialized materials to minimize friction without the need for oil. This results in significantly lower maintenance requirements, as there are no oil changes to perform. Additionally, they deliver cleaner air, making them ideal for applications where oil contamination is a concern. However, oil-free compressors may have a shorter lifespan and are generally less suited for continuous, heavy-duty use compared to their oil-lubricated counterparts.

Key Factors to Consider When Buying a Reciprocating Air Compressor

CFM (Cubic Feet per Minute): Matching Airflow to Your Tools

CFM is a measure of the volume of air the compressor can deliver at a specific pressure. This is perhaps the most critical specification, as it determines which air tools the compressor can effectively power. Each air tool has its own CFM requirement at its operating pressure (usually measured in PSI). It’s generally recommended to select a compressor with an SCFM (Standard Cubic Feet per Minute) rating that is at least 1.5 times the highest CFM requirement of the tools you plan to use simultaneously.

Tank Size (Gallons): Determining Run Time and Duty Cycle

The size of the air tank determines the amount of compressed air the compressor can store. A larger tank allows you to run air tools for longer periods without the motor cycling on and off as frequently, providing a more consistent air supply. Consider the duty cycle of your intended applications – for continuous use, a larger tank is generally preferred.

Maximum Pressure (PSI): Ensuring Compatibility with Your Tools

Ensure that the maximum pressure rating of the compressor meets or exceeds the operating pressure requirements of your air tools. While most tools operate between 90-100 PSI, some specialized tools may require higher pressures.

Power Source (Electric vs. Gas): Considering Location and Portability

Electric reciprocating compressors are the most common choice for workshops and garages with readily available power. They are quieter and require less maintenance than gas-powered models. Gas-powered compressors offer portability and are ideal for job sites or locations without easy access to electricity.

Noise Level (dBA): A Factor for User Comfort

Reciprocating compressors can generate significant noise. If noise is a concern, especially in residential or shared workspaces, consider models with lower decibel ratings or explore noise-dampening accessories.

Portability Features: Wheels and Handles for Easy Movement

If you anticipate needing to move the compressor frequently, look for models equipped with sturdy wheels and a comfortable handle. The size and weight of the unit will also impact its portability.

Duty Cycle Rating: Indicating Continuous Use Capability

The duty cycle refers to the percentage of time the compressor can run continuously versus the amount of downtime required for cooling. For heavy or continuous use, a compressor with a higher duty cycle rating is essential.

Build Quality and Materials: Investing in Longevity

Consider the build quality and materials used in the compressor’s construction. Look for durable components, robust motors, and well-protected pumps to ensure a long and reliable lifespan.

Choosing the Right Reciprocating Compressor for Your Needs:

Selecting the ideal reciprocating compressor involves carefully weighing these factors against your specific applications and budget.

For Home Use and Light DIY Tasks:

A single-stage, oil-free or oil-lubricated compressor with a tank size between 6-20 gallons and a CFM rating suitable for your nailers, airbrushes, and inflation needs is often sufficient.

For Automotive and Medium-Duty Tasks:

A single-stage or smaller two-stage compressor with a tank size of 20-60 gallons and a higher CFM rating will be better suited for impact wrenches, grinders, and some painting applications.

For Professional and Heavy-Duty Applications:

A two-stage, oil-lubricated compressor with a large tank (60+ gallons) and a high CFM rating is typically necessary to power demanding tools for extended periods.

Partnering with a Trusted Air Compressor Supplier:

Choosing the right air compressor supplier is as important as selecting the right compressor. A reputable supplier will offer a range of high-quality reciprocating compressors, provide expert advice to help you make the best choice, and offer reliable after-sales support and service. We pride ourselves on our knowledge and commitment to customer satisfaction.

Conclusion: Powering Your Projects with the Reliability of Reciprocating Technology

The reciprocating air compressor remains a cornerstone of compressed air technology, offering a blend of power, durability, and versatility for a wide spectrum of users. By understanding the fundamental principles of their operation, the differences between single-stage and two-stage models, the pros and cons of oil-lubricated and oil-free options, and the key specifications to consider, you can confidently navigate the selection process. As your trusted air compressor supplier, we are here to guide you in finding the perfect reciprocating compressor to power your projects efficiently and reliably for years to come.

Comments on this guide to Reciprocating Air Compressors article are welcome.

AC Air Compressors

AC Air Compressors Articles

5 key tips for choosing air compressors for company

5 things to check when buying used air compressor

Air Conditioners

Air Conditioners Posts

True cost of poor HVAC maintenance

Indianapolis AC system repairs and troubleshooting

Key things to know about compressor in AC units

Building Articles

Residential Architecture

Comments / photos for the Reciprocating Air Compressors advice page welcome.