Construction industry CNC machines, Manufacture tool, Computer numerical control tips, Gantry systems innovation

Innovation in the Construction Industry with CNC Machines

31 July 2024

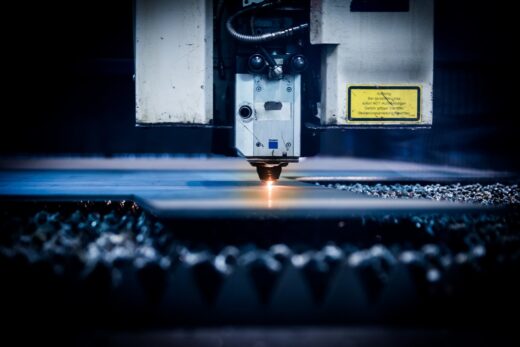

CNC (Computer Numerical Control) machines are revolutionising the construction industry, bringing precision, efficiency, and new design possibilities. These advanced technologies, originally developed for industrial production, are now increasingly finding applications in the construction industry, transforming the way buildings are designed and constructed.

Let’s take a look at the advantages of using CNC machines in industrial applications, and we do it together with the experts from Amastone.com CNC machine tool.

Precision and Efficiency

One of the major revolutions brought about by CNC machines in the construction industry is the ability to perform cutting and machining with unprecedented precision. This level of precision not only improves the overall quality of structures but also significantly reduces waste of materials.

The use of CNC machines enables the exact cutting of beams, planks, and other structural components, ensuring a perfect fit and reducing assembly time on site.

In the construction of wooden homes, CNC machines can precisely cut timber beams and joints, ensuring that each piece fits perfectly with minimal gaps, thus enhancing the structural integrity and insulation properties of the building.

Applications in Residential Construction

CNC machines are becoming increasingly popular in home construction due to their ability to automate complex and repetitive processes.

These machines can be used to manufacture components such as wall panels, prefabricated modules, and even decorative elements with intricate detailing. This approach not only speeds up the construction process but also allows for greater customization of the design, meeting specific customer requirements.

CNC machines can be used to create customized cabinetry and intricate trim work that matches the unique architectural style of a home, providing a personalized touch while maintaining high efficiency.

Integration with CAD Software

Another key aspect of using CNC machines in the construction industry is their integration with computer-aided design (CAD) software. This combination allows CAD drawings to be directly exported to CNC machines, which can then produce components exactly as designed.

This process reduces human error and ensures that designs are produced to precise specifications. For example, software such as ArchiFrame allows beams, planks, and other structural elements to be set directly from CAD exports, further optimising the construction process.

In a large-scale commercial project, architects can use CAD software to design complex structures. These designs are then fed into CNC machines, which produce the structural components with exact specifications, ensuring the building is constructed as intended without deviations.

Economic and Environmental Benefits

The adoption of CNC machines also brings significant economic and environmental benefits. Improved efficiency reduces labour and material costs, while machine precision minimises waste.

In addition, the use of pre-fabricated components produced with CNC machines can significantly speed up construction times, allowing projects to be completed in shorter timescales than traditional methods.

By using CNC machines to produce prefabricated building modules, for example, a construction company can drastically reduce on-site construction time and labour costs, while also minimizing material waste, contributing to more sustainable building practices.

Expanded Applications in Commercial and Industrial Construction

Beyond residential construction, CNC machines are increasingly used in commercial and industrial projects. Their ability to produce complex, large-scale components with high precision makes them ideal for constructing intricate facades, large steel frameworks, and other structural elements critical in commercial buildings.

In the construction of high-rise buildings, CNC machines can be used to fabricate steel beams and connectors with precision, ensuring that the structural framework is robust and meets all safety standards.

Future Prospects and Innovations

The future of CNC machines in the construction industry looks promising, with ongoing innovations leading to even greater capabilities. Advances in materials, machine learning, and AI integration are expected to enhance the functionality and efficiency of CNC machines, allowing for more sophisticated and sustainable building practices.

Those machines are truly transforming the construction industry, introducing new possibilities for precision, efficiency, and customization.

Comments on this guide to Construction industry CNC machines article are welcome.

CNC Wood Routing Work

Woodworking Posts

Guide to CNC Machining and its purposes

Basic principles of CNC Machine

How to plunge cut with a fixed base router

How to set up a CNC machine shop

Professional carpenter and handyman services for home

Property Articles

Architecture

Comments / photos for the Construction industry CNC machines advice page welcome