Basic principles of CNC Machine advice, Computer numerical control tips, Gantry systems guide

Basic principles of CNC Machine

14 September 2022

If you’re new to the manufacturing industry, you’ve likely heard of CNC machining, but you’re not sure what it is and how it benefits manufacturing firms and factories. This type of manufacturing machine is a very advanced and ever-improving system that helps factories and manufacturing companies deliver high-quality products at low prices in high volumes. Read on to learn more!

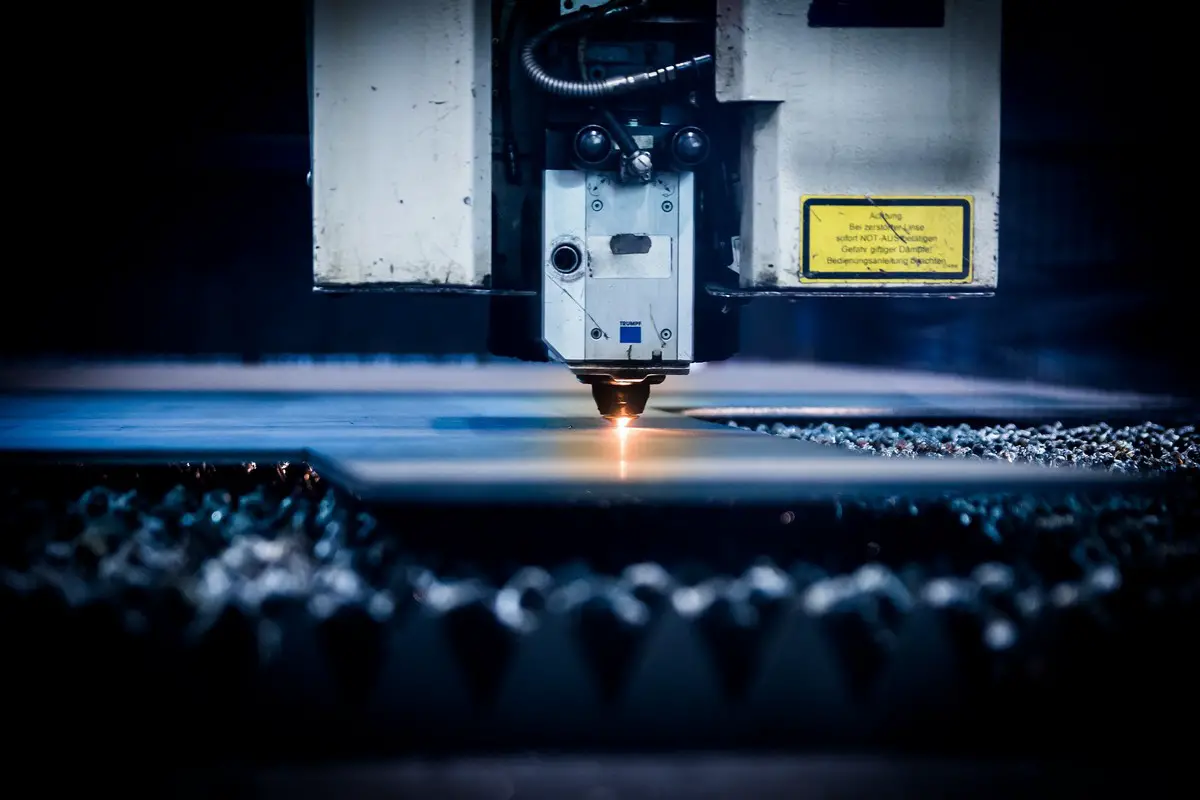

Basic principles of CNC Machine – industrial machining

First, what can CNC machining do? Basically, this industrial machine has one job: to extract pieces of metal, plastic, or other material from a larger block of material to form a shape, which then becomes a component or product. The method may be different but the basic outcome of every method is the same, to get the required shape of the object.

So how does the machine do it? The clue is actually in the name, CNC stands for Computer Numerical Control. At the heart of all CNC machining is a central computer, which is fed data from a CAD program, or computer-aided design application. The CNC computer is connected to the lathe itself, and so the entire process of metal shaping in three main ways is fully automated by the machine. One of the main advantages of this system is that each machine can be reprogrammed using a single piece of software to accommodate different roles.

For example, if a factory has ten machines, they can all be assigned to milling one day, drilling the next, and lathe the next. Compare this to a manual machine, where valuable factory floor space needs to be filled with machines that cannot be reprogrammed. This means that some machines will be idle on certain days and the maximum productivity of the factory will not be achieved.

Unlike a manual lathe or milling machine, a computer knows exactly what to do, so no skilled technician is needed. Instead, a CNC machining system technician is assigned to a manager, who maintains the system, and ensures that it is fully functional and easy to work with. There is plenty of material for that.

Another aspect is that one technician can manage multiple machines, perhaps between 3 and 5 at a time, which means that one technician can increase their productivity fivefold. However, even if not actively engaged in any manual milling, lathing, or drilling, the technician must be trained in these skills, as this knowledge is essential to operating these machines.

Since CNC machining equipment is fully computer controlled, precision is something that comes as standard. A computer-controlled lathe has a more stable hand than a manual technician, so unprecedented levels of precision can be achieved. CNC router machine is actually now the industry standard and necessary for the level of precision required for most components as manually manufactured products cannot compete.

Comments on this guide to Basic principles of CNC Machine article are welcome.

CNC Wood Routing Work

Woodworking Posts

Guide to CNC Machining and its purposes

Guide to CNC Machining and its purposes

Professional carpenter and handyman services for home

How to plunge cut with a fixed base router

CNC designed architectural interiors with wood routing

Property Articles

Architecture

Comments / photos for the Basic principles of CNC Machine advice page welcome