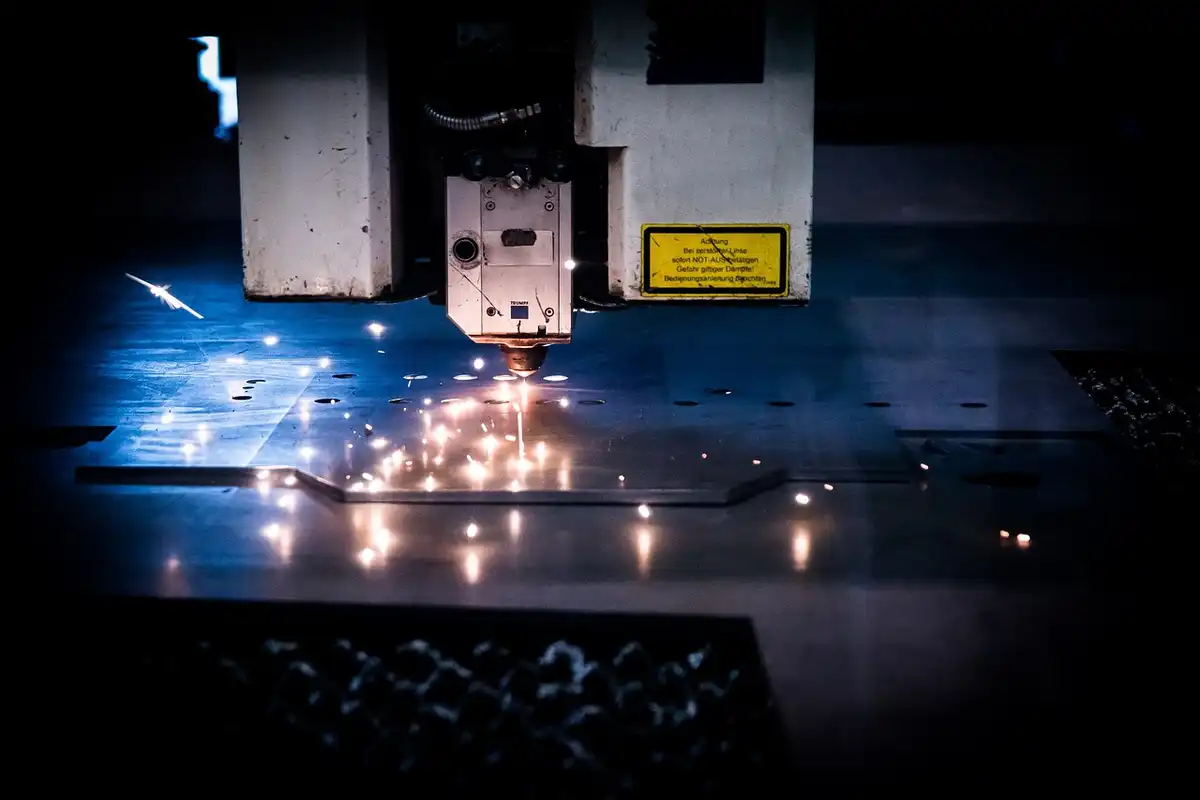

CNC plasma cutting for large-scale architectural installations, Construction industry machines, Manufacture tool

CNC Plasma Cutting for Large-Scale Architectural Installations

10 June 2025

Why CNC Plasma Cutting Is a Game-Changer for Large-Scale Architectural Installations

Have you noticed how public spaces and buildings are incorporating bolder metal elements into their design? Think about the sharp edges of a sculptural gate or the layered cutouts on a steel façade.

Behind these designs, there’s a process helping architects move from sketches to finished parts with more speed and control than ever before. That process is plasma cutting, guided by computer numerical control (CNC) technology.

This method is gaining popularity, especially in architectural work where accuracy and scale are crucial. But what makes it so effective? And why are design and fabrication teams switching to it?

Let’s walk through it together and unpack why this approach is changing how big ideas get built.

Accurate Results That Are Easy to Repeat

In large builds, a single mistake in one part can affect the whole project. A panel that’s too wide, a corner that’s not clean—small flaws can become big setbacks. That’s why consistency is so valuable. Plasma cutting machines, controlled by CNC software, allow each piece to follow the same pattern with little room for error.

You don’t need to keep checking measurements or making adjustments by hand. The system reads the digital file and delivers the exact cut each time. This helps when multiple panels need to align or repeat across a structure. Builders get what they need, and designers know their vision will hold up, even at scale.

What Makes the System Work So Well

Let’s talk about the engine behind the process. While the torch gets most of the attention, the real foundation is the CNC plasma table, which handles both precision and motion. This isn’t just a flat surface—it’s a system that supports control at every step.

The table works with software to move the torch smoothly. It keeps materials stable and adjusts for height automatically. If you’ve ever watched a machine like this in action, it’s easy to see the difference. The result? Cleaner cuts, less waste, and a faster path from file to finish. It simplifies things without losing quality, which is something every team can appreciate.

More Room to Be Creative

Not every architectural detail fits into a box. Some projects call for curved shapes, layered metal, or unexpected patterns. That’s where flexibility becomes a real advantage. CNC-guided plasma systems allow teams to take design files and bring them to life without needing to retool or reprogram the machine each time.

Want to experiment with a mix of rounded and angular shapes? You can. Need a fast way to adjust a panel’s layout based on a site change? That’s doable, too. The ability to update a digital design and see it cut within minutes makes it easier to stay creative without slowing the build. It’s not just about making what works—it’s about trying what’s possible.

Helps Large Projects Run Smoother

When you’re managing a major build, timing matters. You’re often juggling teams, suppliers, weather, and budgets. Plasma systems help reduce surprises. Once the design is finalized, it’s sent directly to the cutter. That removes the need for hand-cutting, outsourcing, or waiting for third-party shops to deliver.

Need to make a change mid-project? The file can be updated and re-cut without disrupting everything else. This kind of control helps project managers stay flexible without adding stress. It also keeps things moving forward on-site. When parts arrive ready to install, the whole job stays on schedule.

Supports Many Types of Metal

Every project has its own material needs. One may call for brushed aluminum. Another needs thick, weathered steel. Plasma systems can handle both, along with other metals like copper or stainless steel. The cut quality stays high, even when switching materials or thicknesses.

This matters when your project includes a mix of elements. Instead of using different tools for different materials, a single system can handle it all. That keeps the process simple and helps avoid gaps in the workflow. Plus, it lets designers choose materials based on performance or aesthetics, not tool limitations.

Makes Teamwork Easier

Architectural work is rarely done alone. Designers, engineers, fabricators, and contractors all have a role. What helps tie everything together is a shared system. With this method, everyone works from the same digital files. There’s no need to redraw or explain how something should be cut.

This makes handoffs smoother. The designer can export a file that the cutter reads directly. If a change is needed, it can be made once and used by all. That keeps everyone aligned and cuts down on errors. Good collaboration isn’t just about meetings and updates. It’s about using tools that connect the team from start to finish.

Conclusion

CNC plasma cutting brings speed, accuracy, and flexibility to a field where all three matter; for architectural teams working on big, visible projects, that can make a huge difference. The process doesn’t just reduce effort—it adds more ways to get creative, solve problems, and deliver work that stands out. If you’re building big, it might be time to think small, starting with the precision of every cut.

Comments on this guide to CNC plasma cutting for large-scale architectural installations article are welcome.

CNC Wood Routing Work

Woodworking Posts

Guide to CNC Machining and its purposes

Basic principles of CNC Machine

How to plunge cut with a fixed base router

How to set up a CNC machine shop

Professional carpenter and handyman services for home

Property Articles

Architecture

Comments / photos for the CNC plasma cutting for large-scale architectural installations advice page welcome