Aerogel Material climate-resilient buildings, Net zero carbon design, Sustainable architecture

Aerogel Wonder Material for Climate-Resilient Buildings

post updated November 2, 2024

Wonder Material Aerogel could be the key to Climate-Resilient Buildings

Article by Pitamber Kaushik

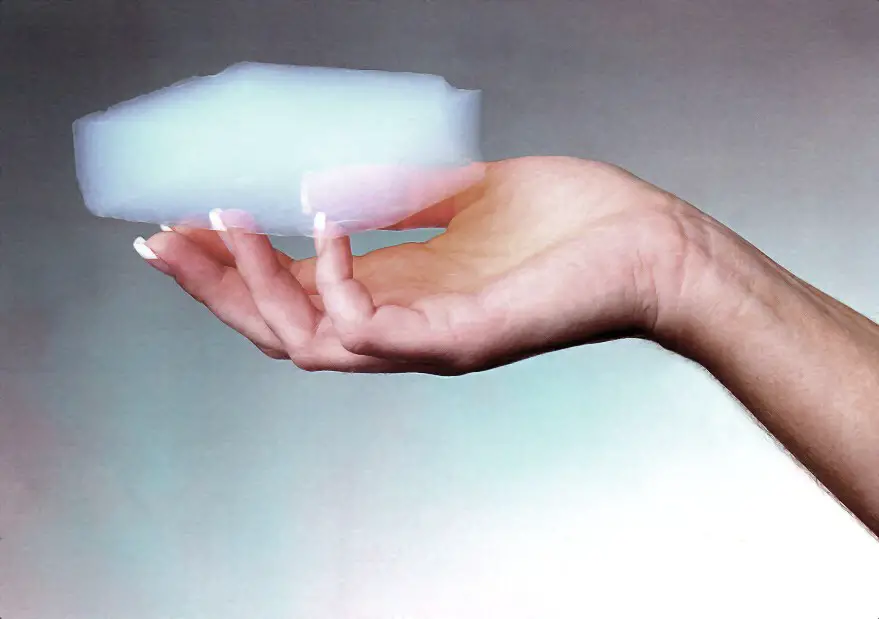

Aerogel hand – a block of silica aerogel:

photo Courtesy: NASA/JPL-Caltech – NASA Stardust Website (Public Domain)

29 October 2022

Aerogel Wonder Material for Buildings

Intensifying with each passing year, Climate Change is wreaking havoc around the world and heatwaves are one of its deadliest manifestations. From China to the US, heat waves are shattering historic records, precipitating ramifications ranging from upset livelihoods, impeded economic growth, and disrupted power supply to worsening mental health, increasing incidences of stroke, and increased risk of stillbirths, among others.

According to the World Meteorological Association, there is now a 50% chance of the average annual global temperature touching the 1.5 degree mark above pre-industrial level for at least one year in the next five years. The 2021 Intergovernmental Panel on Climate Change Report showed that human-made climate change had caused a 1.1 degree rise in average global temperature since the second half of the 19th century, and the rise would reach a consolidated 1.5 degrees expectedly in the next two decades. Coastal and island societies and economies would be the worst-hit. The Global South is likely to be disproportionately affected, unjustly bearing the brunt of both the physical as well as the socioeconomic consequences of the climate crisis majorly contributed to by First-World nations.

With rapid population growth, urbanisation, and rural-to-urban migration, quantitative coping measures might start to seem increasingly unrealistic or unviable. In the era of globalist capitalism, half-hearted regulatory policy measures seem to accomplish too little, too late. While striving for top-down crisis management strategies and pushing for legislative intervention are important, qualitative, intensive, grassroots innovation can enable vulnerable communities and localities to mitigate the effects of climate change. Given the pressing need for expansion of housing, rising land and infrastructure costs, and an urgency to mitigate urban construction-impressed footprint, architecture needs to focus on qualitative optimisation and take a bottom-up approach to sustainable planning and design. Material science can help supercharge coping and mitigation strategies while keeping costs and lateral footprints in check.

Aerogel flower – a tile of silica aerogel protects a flower from the flame of a bunsen burner:

photo Courtesy (Public Domain)

The quest for construction materials for coping with climate warming naturally leads us to thermal insulators. Thermal insulation is a research hotspot and many new efficient heat-deterring materials have been synthesised over the past decades. However, much of the research in the area concerns itself with the development of effective insulation for uses in specific activities, ranging from electronics to speciality protective gear and equipment to aeronautics and spaceflight.

The impending heating crisis in Europe as a result of the retraction of gas supply by Russia has reinvigorated the dormant discussion around better housing insulation that helps to preserve heat and thus conserve energy.

It is a matter of intrigue that few, if any, have intuitively turned to the world’s best insulator, aerogel, to respond to these thermodynamic challenges. Aerogels are a class of materials which consist of a gas dispersed through a fine matrix of solid – a gel with a gas in place of the liquid component. Aerogels are made by removing the liquid dispersed in a solid matrix in such a way that it doesn’t cause the latter to collapse, leading behind an intricate, fine, cross-linked solid structure with many tiny empty pockets.

Aerogels can be made from silica, carbon, ceramics, and metals, among others. Each material exhibits different properties which can be fine-tuned by controlling the size and numerosity of pores during the manufacturing process. These properties can further be manipulated by the use of additives. A typical aerogel is 99.8% air and hence is ultra-lightweight – only 15 times heavier than air, about 200 times lighter than glass. Despite its low density, the extensive cross-linked structure of the solid matrix lends it one of the highest strength-to-weight ratios of all materials.

Put in simple terms, the tiny amount of solid that is present in a piece of aerogel, is so strategically distributed and intricately structured that it optimises the strength per unit weight of the solid. Aerogels can thus support weights of the order of a few thousand times their own weight. This might tempt one into assuming aerogel to be a wonder-material for construction. However, conventional aerogels like silica aerogel can only support the weight if it’s well-distributed and tend to crumble under sudden, sharp impulses.

Although aerogels boast an extraordinarily high supportive strength for their weight, their extremely low density means that their strength in the absolute sense remains humble. This had prevented any significant structural application. However, various new techniques have been devised that can considerably reduce the brittleness and friability of aerogels, customising them to be flexible or sturdy as desired. Different varieties of aerogel may exhibit widely different mechanical properties especially upon being treated by physicochemical reinforcement or restructuring processes.

Many aerogels are highly compressible, longitudinally or bulk straining to be compacted to half their volume and still not shattering or yielding – they restitute from the deformation as soon as the stress applied is lifted. Ongoing research is yielding new aerogel materials as well as different kinds of treatments to reinforce them and alter their mechanical properties to make them practically-applicable.

Aerogels have an extremely low thermal conductivity.since the air pockets in them are so minute that they effectively lock gas particles within them, a phenomenon called the Knudsen Effect, hindering conduction and eliminating convection. The nanometre-scale pores trap molecules cutting the thermal conductivity of the gas multifold.

Aerogel brick – a 2.5 kg brick supported by a 2 gram piece of aerogel:

photo Courtesy: NASA/JPL-Caltech – NASA Stardust Website (Public Domain)

The complex microporous structure of the aerogel lends a single inch-cube piece of the material an internal surface area of about a football field, leading to exceptional molecular-level organisation that lends it some very interesting properties. To get an idea of how well aerogel deters heat flow, consider the fact that a centimetre-thick plate of aerogel can keep a piece of chocolate or a dollop of butter from melting when heated with a blowtorch or burner from underneath.

Aerogels can still permit heat through radiation but the addition of infrared opacifiers to them has proven effective in making them ultra-efficient, versatile, and robust all-round insulators. Further, the fact that aerogels permit infrared radiation can prove to be useful in radiative cooling whereby aerogels block conductive and convective heat from entering but let existing heat radiate out. Many aerogels intrinsically have or can be engineered to have ultra-efficient sound-proofing and water-proofing properties, attributes which would prove vital in climate-susceptible, densely-populated urban environments.

NASA is using aerogel to catch space-dust for study and keeping its martian rover warm, owing to its unique mechanical and thermal properties. It is interesting how the material is being widely considered for its prospective role in insulating martian colonies before being considered seriously for infrastructural applications here on the Earth.

Aerogels are commonly made from silica, carbon, and metal oxides like alumina and iron oxide. Most of these materials are abundant and easy to procure – silica and alumina, for instance, make up four-fifths of the Earth’s crust. The raw material costs are thus typically very low, however, the creation of the aerogel is a sophisticated, delicate, and precise process, which leads to the finished product being priced extremely dearly and nigh-stagnating at being an ‘avant-garde’, ‘futuristic’, or ‘experimental’ product since its creation nearly a century ago. Although something made of air and minerals like silica may seem to pose no environmental problem, the sophisticated, precise process of production of aerogels consumes a sizable bit of energy.

Aerogels currently sell at thousands of dollars per kg, a figure that seems more intimidating than it should, given that aerogels are extremely rarefied (low density). But even the price per cubic centimetre of the material isn’t the most agreeable of figures – a less than appealing range of 20-200 dollars. Nonetheless, multiple university teams and select material technology companies around the world are working on cutting costs by improving the existing manufacturing processes as well as devising new, cost-effective ways to create aerogels. Aerogel panels are gradually becoming increasingly commercially viable and diversified in terms of size and shape.

Aerogels can be modified to be made considerably waterproof and elastic, essential for affording resilience in climactic weather. Treatments can also enhance the crosslinking of aerogels, at differing expenses to other properties. Aerogels can be made to catch or repel particles and fluids, which can prove useful in structural design in different environments.

Graphene, itself a wonder-material with immense potential, is being experimented with, to develop superior aerogel-like materials (having similar, at times even-more pronounced superlative properties). Creating aerogel-like materials from graphene involves a fundamentally different process where nanostructures are grown on a surface instead of replacing a liquid with a gas in a gel framework. In 2013, Chinese scientists developed a graphene aerogel claimed to be the world’s lightest material, lighter than most gases. The material could recover to its original size even after 90% compression, a testament to its elastic resilience. They developed this by freeze-drying a solution, a method that is readily scalable as any practical desired size of graphene aerogel can be created by using an accordingly-shaped mould for the solution. Some graphene aerogels are already expected to become commercially viable in the next decade.

In 2019, a team of researchers from the Massachusetts Institute of Technology and Pontifical Catholic University of Chile devised a novel aerogel-based device that could provide cooling without electricity by blocking out incident sunlight but letting heat radiate out. This device could cool things shielded by it by up to 13 degrees Celsius. If such materials could be made commercially viable, the domain of applications could range from cold storages and water tanks to housing complexes and office blocks. Heating and cooling processes everywhere from domestic to industrial settings are major contributors to climate change. The super-efficient thermal insulation afforded by aerogels could help greatly reduce the footprints of these processes.

According to a 2015 European Commission’s Business Innovation Observatory report on Advanced Materials, the global aerogel market was valued at EUR 250 million and the total purchase quantity amounted to just over 10000 metric tons in 2014, with the Oil & Gas Industry being the biggest buyer claiming a 74% chunk of the total purchase and thermal & acoustic insulation following a distant second at 8% share. While the amount might sound a lot, it is not – consider the fact that the figures for consumption of PVC and Polystyrene globally are over 50 million and 15 million metric tonnes respectively. The global insulation market itself was EUR 34 billion in 2014 and expected to grow to 50 billion in the following decade. The same report asserted that the aerogel market was expected to grow with increasing demand for high-quality insulation. It also reported a promising rise in patent registrations and R&D Investments in Aerogel production.

In 2018, a cross-institution team of scientists and experts from Newcastle University, Durham University, Limerick University, and the Museum of Bosnia and Herzegovina created a type of strong, sturdy aerogel through a liquid replacement (by gas) process using bicarbonates, inspired by the metamorphosis of a dragonfly and emergences of its wings (which happen to be an ultralight gas-in-solid gel as well). The researchers stated that their biomimicking process innovation would bring down the cost of aerogel production by 96%, from $100/kg to $4/kg.

Such developments point to the promising potential of aerogels. The class of materials is undergoing further refinement as increasingly sophisticated variants are appearing every few years, often tailor-made to serve specific purposes. The key is to find a commercially-viable and sustainably-producible material that provides the requisite thermostructural integrity in the context of the modern climate crisis and urbanisation pressure.

A number of porous, lightweight insulators like polystyrene foam are non-biodegradable practically non-recyclable synthetic hydrocarbon polymers. They are cost-effective and easy to mass-produce but would impress a sizable environmental footprint when used in short life-cycle infrastructure components. The same goes with carbon-based aerogels, which are multifold more effective than conventional polymers. Carbon-based neo-materials have a great potential in material science and engineering.

Carbon is abundant, readily concatenates, and hydrocarbon polymers are relatively easy to tweak to imbue them with specific properties customised to serve specific needs. Physical refining processes, chemical treatments, and nanoengineering are churning out new, advanced, and increasingly sophisticated polymer-based materials year after year. Aerogels are no exception. However, it is vital to ensure that such materials be judiciously deployed. Their usage in fast-moving construction could have an adverse impact on the environment given their ready availability and careless disposal.

Modularisation, say in the form of panels or standardised sheets would facilitate recycling and an end-of-life-cycle collection mechanism needs to be in place for the same. Since the materials require significant physical and chemical treatment, reusing and recycling them would help cut down on a major portion of their manufacturing footprint. Centralising and consolidating the basic manufacturing process to enable mass production would help cut down on footprint per unit weight of such materials.

The ability to drastically alter the properties of aerogel using additives makes aerogel a promising class of materials with diverse possible applications. Aerogels can prove to be a wonder material for civil engineers in building climate-resilient structures which themselves impress as small a footprint as possible. Establishing reverse logistic routes for discreet collection of aerogels upon deconstruction of such structures and their ready recycling would further diminish their footprint.

Robotics and 3D-printing can help speedily manufacture enough aerogel to help meet growing infrastructural demands in our dynamic environments. Owing to their extraordinarily high thermal and structural resilience to weight ratio and ready customisability (through controllable intrinsic parameters), aerogels are some of the most promising materials for a smart, sustainable future, which have long evaded the glance of architects and civil engineers.

With their customisability and versatility, aerogels have the potential to provide architects new creative avenues. By cutting down on bulk, aerogels can enable architects to push their imaginative frontiers and design for the future with the lightest solid material on Earth while allowing civil engineers to maximise utility and minimise both the causes and effects of climate change on buildings.

About

Pitamber Kaushik is a writer, journalist, columnist, educator, and independent researcher. His writings have appeared in over 170 publications across 50+ countries. He is currently based out of Xavier Labour Relations Institute, Jamshedpur, India.

Aerogel Wonder Material: Climate-Resilient Buildings image / information received on 291022

Previously on e-architect:

Net Zero Carbon Buildings News

Zero carbon Interiors

photo courtesy of Mick de Paola, unsplash

Zero carbon Interiors

Scott Brownrigg Award for Sustainable Development

photo courtesy of The Royal Institute of British Architects

RIBA Scott Brownrigg Award for Sustainable Development

WorldGBC and GRESB join forces to drive net zero carbon buildings

photo courtesy Anders Vestergaard Jensen, unsplash

Net Zero Carbon Buildings

Zero Carbon Buildings 2050 Report

House of Lords Zero Carbon Homes Ruling

Eco Architecture

Contemporary Green Architecture Design – selection of posts:

2020: The Year of Net Zero

photo © Richard Glover / Matt Estherby

Sustainable Building News: Zero-Energy

Climate and Biodiversity Emergency

photo : Tim Griffith

Climate and Biodiversity Emergency

Buildings / photos for the Aerogel Wonder Material: Climate-Resilient Buildings – Sustainable Design News page welcome