Precision and power: the future of hydraulic repairs unveiled, Property drainage advice, Residential building plumber

Precision and Power: The Future of Hydraulic Repairs Unveiled

10 January 2025

Hydraulic systems are the unsung heroes of modern industry, powering everything from construction equipment and manufacturing machinery to airplanes and ships. These systems rely on the power of fluids to generate, control, and transmit force, enabling heavy lifting, precise movements, and efficient operations across various sectors.

However, these complex systems are not immune to malfunctions, and components like cylinders can suffer from wear and tear, leading to leaks, reduced efficiency, and even complete system failure. The efficiency of these systems is paramount, and any malfunction, including the need for cylinder repairs, can lead to costly downtime and safety hazards. This is where the importance of precision and power in hydraulic repairs comes into play. As industries evolve and demand more from their machinery, the need for advanced hydraulic repair solutions has never been greater.

The Evolution of Hydraulic Systems and Their Repairs

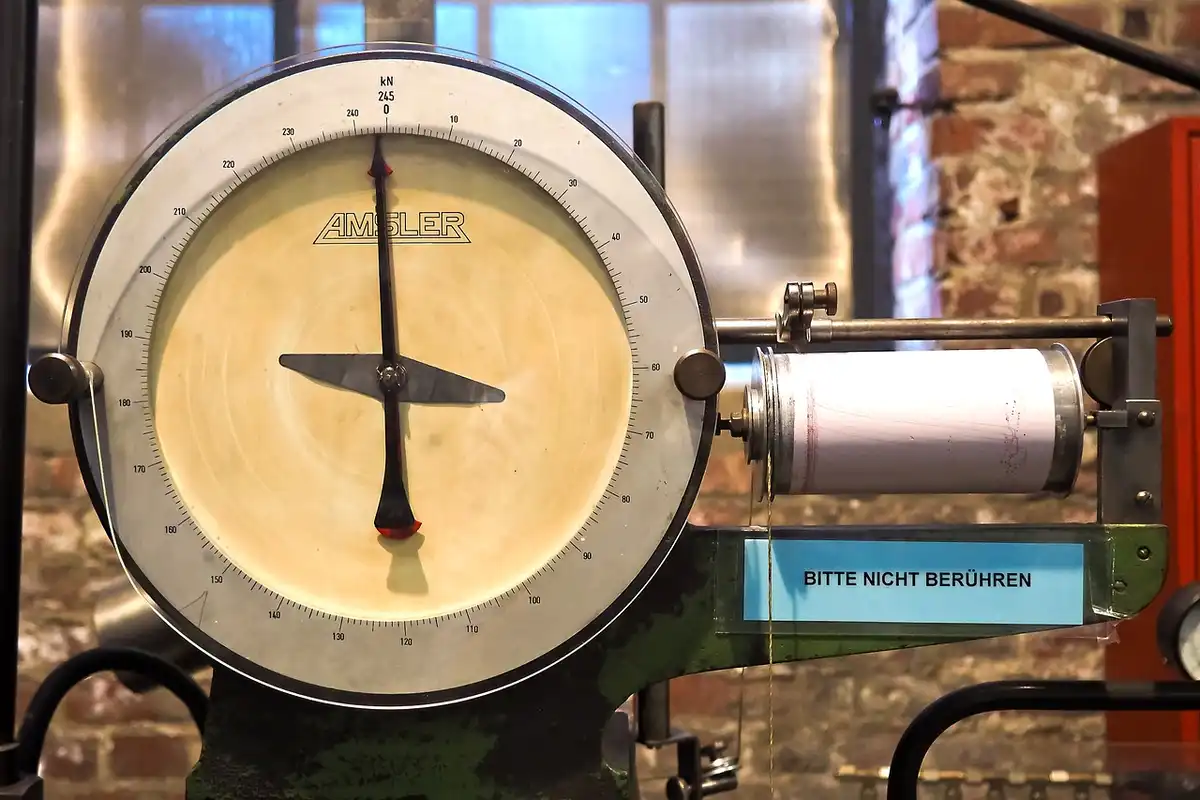

The concept of hydraulics dates back to ancient times, but it wasn’t until the Industrial Revolution that hydraulic systems began to take shape in their modern form. Early hydraulic systems were relatively simple, employing basic principles to power machinery. Repairs often involved manual adjustments and replacements of rudimentary components. However, with advancements in technology, hydraulic systems have become increasingly complex, incorporating sophisticated components and intricate designs. This evolution has led to the development of specialized tools and techniques for hydraulic repairs, demanding a high level of expertise and precision.

The Role of Cylinders and Rams in Converting Hydraulic Pressure

At the heart of any hydraulic system lie its core components: cylinders, rams, and pumps. These components work in harmony to generate and transmit hydraulic power, enabling the system to perform its intended function. Cylinders and rams, in particular, are responsible for converting hydraulic pressure into mechanical force, making them crucial for tasks such as lifting, pushing, and pulling.

However, these components are subjected to immense pressure, temperature fluctuations, and continuous wear and tear, making them prone to damage. Understanding the intricacies of these components is essential for effective repairs and rebuilds, ensuring the longevity and optimal performance of the hydraulic system.

The Role of Hydraulic Repair Shops in Modern Industry

In today’s fast-paced industrial landscape, hydraulic repair shops serve as vital lifelines for businesses that rely on heavy machinery. These shops are equipped with the specialized knowledge, tools, and equipment necessary to diagnose and repair complex hydraulic systems. Skilled technicians in these shops can identify the root cause of a problem, whether it’s a faulty pump, a leaking cylinder, or a damaged ram. By providing timely and efficient repair services, hydraulic repair shops help minimize downtime, optimize productivity, and ensure the smooth operation of critical equipment across various industries.

Pros and Cons of Hydraulic Systems

Pros:

- High Power Density:Hydraulic systems can generate immense power from a compact unit, making them ideal for heavy-duty applications.

- Precise Control:Hydraulic systems offer precise control over movement and force, allowing for delicate operations as well as powerful actions.

- Durability and Reliability:With proper maintenance, hydraulic systems can withstand harsh operating conditions and provide reliable performance for extended periods.

- Versatility:Hydraulic systems can be adapted to a wide range of applications, from construction and agriculture to aerospace and manufacturing.

Cons:

- Potential for Leaks:Hydraulic systems rely on fluids under high pressure, making them susceptible to leaks, which can be messy and hazardous.

- Maintenance Requirements:Regular maintenance is essential to prevent leaks, wear and tear, and other issues that can compromise performance and safety.

- Noise and Vibration:Hydraulic systems can generate noise and vibration, which can be a concern in some applications.

- Environmental Concerns:The use of hydraulic fluids raises environmental concerns, particularly if leaks occur or fluids are not disposed of properly.

Hydraulic Ram Rebuild: Restoring Power and Precision

When a hydraulic ram suffers significant damage or wear, a complete rebuild may be necessary to restore its functionality and performance. A hydraulic ram rebuild involves disassembling the ram, inspecting each component for damage, replacing worn-out parts, and reassembling the unit with precision. This process not only addresses the immediate issue but also extends the lifespan of the RAM, ensuring its long-term reliability. In many cases, a hydraulic ram rebuild offers a cost-effective alternative to replacing the entire unit, saving businesses time and money.

Innovations in Hydraulic Repairs: Technology and Techniques

The field of hydraulic repairs is constantly evolving, with new technologies and techniques emerging to enhance precision, speed, and overall repair quality. 3D printing is revolutionizing the way replacement parts are manufactured, allowing for the creation of custom components with intricate designs. Laser welding provides a highly accurate and efficient method for joining metal parts, ensuring strong and durable repairs. Furthermore, AI diagnostics are being used to analyze system data and identify potential problems before they escalate, enabling proactive maintenance and preventing costly failures. These innovations are transforming the hydraulic repair landscape, making repairs faster, more accurate, and more efficient than ever before.

Customer Examples

Positive:

- Construction Company:A construction company relies on hydraulic excavators for earthmoving operations. Regular maintenance and timely repairs from a trusted hydraulic repair shop ensure minimal downtime and keep their projects on schedule.

- Manufacturing Plant:A manufacturing plant utilizes hydraulic presses for shaping metal components. By investing in preventative maintenance and utilizing advanced diagnostic tools, they avoid costly breakdowns and maintain consistent production output.

Negative:

- Agricultural Farm:A farm experiences frequent breakdowns in its hydraulic-powered tractors due to neglecting regular maintenance. This results in delays during harvest season and significant financial losses.

- Shipping Company:A shipping company faces safety concerns due to a leaking hydraulic system on one of its cargo vessels. The leak leads to environmental damage and costly repairs, highlighting the importance of proactive maintenance and prompt repairs.

Conclusion

In conclusion, the demand for precision and power in hydraulic repairs is only going to intensify as industries continue to evolve and rely on increasingly complex hydraulic systems. From understanding the core components to embracing innovative technologies and sustainable practices, the field of hydraulic repairs is transforming. By staying at the forefront of these advancements, hydraulic repair shops can ensure the seamless operation of critical machinery, driving efficiency and productivity across various sectors. The future of hydraulic repairs is bright, powered by innovation, sustainability, and an unwavering commitment to precision and power.

Comments on this guide to Precision and Power: The Future of Hydraulic Repairs Unveiled article are welcome.

Plumbers and Plumbing

Plumbers Posts

Do you need plumber to install hot water heater

How to Know If a Plumber is Good

Practical tips for architects when designing plumbing systems

What to check before finalizing a plumbing service

Building Articles

Comments / photos for the Precision and Power: The Future of Hydraulic Repairs Unveiled page welcome