Cutting steel to size for your projects guide, Sheffield guillotine blades tips, Industrial cutter

Cutting Steel to Size for your Project

7 Dec 2021

Constructing a building or architectural piece out of steel can have severe financial implications, especially if you order the wrong size steel and need it cut.

The best option is to be sure of the dimensions you need. However, we all know that is harder said than done. The following alternative would be to cut the steel structure or piece using an industrial guillotine cutter.

You’ll find an expert specialising in cutting steel that supplies the highest quality guillotine blades if you shop around. In addition, they’ll advise you on the best method to cut and ultimately save you money in the long run. Learn more about guillotine blades and how they can help cut your steel to the correct dimensions.

If you do manage to get your hands on a machine capable of cutting, such as squaring shears, power shears or a guillotine machine, we’ve put together some helpful tips below.

Top tips for cutting steel to the correct size

- Protection: the first tip would be to ensure you have adequate personal protective equipment to carry out the job. Cutting steel can cause serious injury if not performed correctly.

- Cut to the correct size: depending on the steel measurements needed, you’ll need to ensure the machine is set up to cut to the desired length, angle, shear angle and rake angle.

- Ensure blades are sharp: one of the essential elements is to ensure the knife you’re using to cut the steel is sharp. Often, if a manufacturer has been using the blade for a lengthy time, the knife may become dull.

- Take time to set up the machine: if you’re setting up the device to cut your steel to size, take your time to get the guards in the correct place. The machines can cut through steel, so they won’t have trouble removing a limb if you’ve not set it up correctly.

- Don’t remove the steel by hand: the machine should automatically drop your newly cut steel out of the catch tray. If it does not, don’t stick your hands in there. Sometimes, steel can become stuck, and the blades will be jammed. Instead, call an expert to get your piece out of the machine.

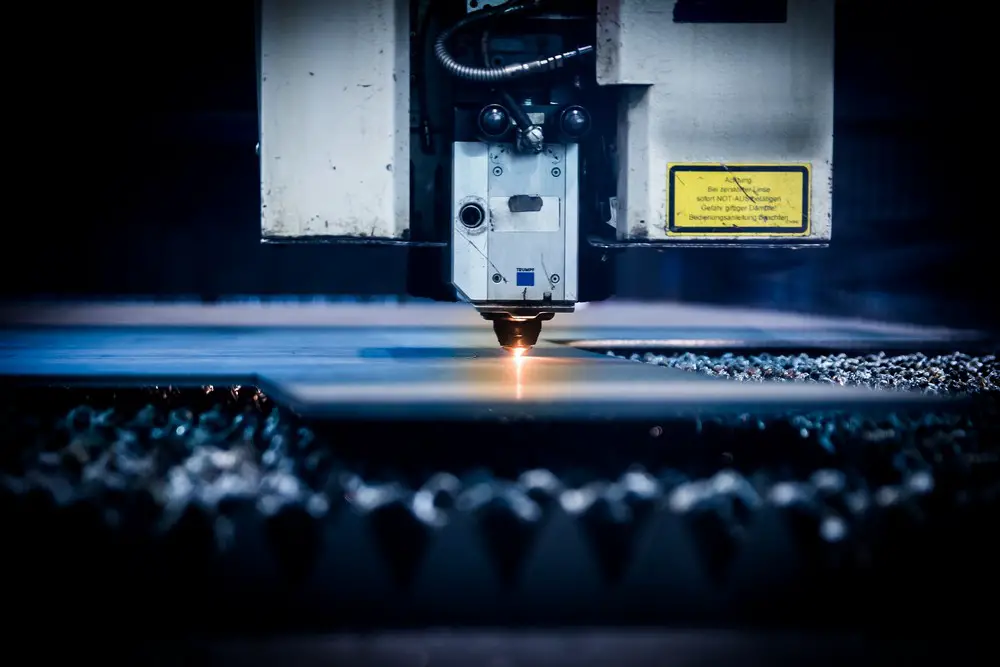

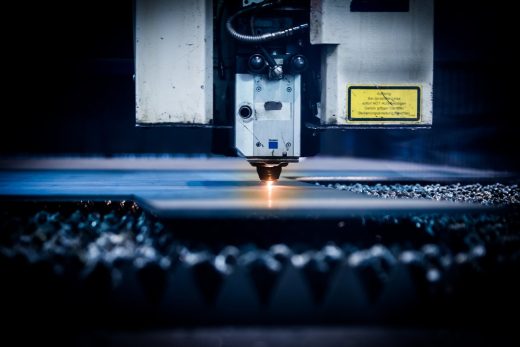

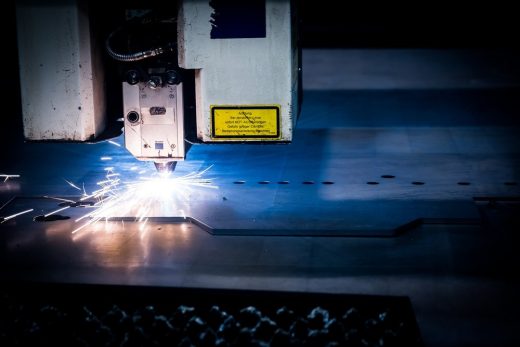

How do guillotines cut steel?

Industrial guillotines operate by a clamp securing the steel. Furthermore, they cut steel by using two blades. First, a fixed knife works under the piece and the second slices down to cut the steel to size and dimensions the machine has been set up for. The cut, which can otherwise be referred to as cropping, is the same throughout all the different types of blades; shears, plates, squares, beverly and groove.

These industrial knives are not like your standard blade. Instead, they have well-defined edges that can cut through highly robust materials. In addition, the top and bottom blades work together to produce a powerful cut to your steel. It is recommended that you often turn your blade over if you’re cutting many pieces, but I would imagine you’re only using it for one architectural structure. If you don’t turn it over, expect the edges to become dull quickly.

Cutting steel to size for your project Conclusion

No matter if you’re producing staircases, architectural pieces or forming the structure of a building. Ensuring the steel you have ordered is of the correct dimensions is very important.

If not, you’ll have to find an expert company to cut your steel to size or hire a machine yourself to cut. The second option can be very costly in the end, but with our tips, you will hopefully understand how to cut the structural piece to the correct size.

Comments on this Cutting Steel to Size for your Project article are welcome.

Building Articles

Residential Architecture

Comments / photos for the Cutting Steel to Size for your Project page welcome