Prefabricated modules and modular construction, Building bathroom pod guide, Home prefab

Prefabricated modules and modular construction: A trend that is here to stay

22 Dec 2022

Modular construction using prefabricated modules is a booming trend that is steadily gaining ground in the construction industry. In recent years, this type of construction has penetrated strongly in markets such as Europe, the United States, and Asia.

So, it doesn’t come as a surprise that we are seeing more large-scale projects such as hospitals, nursing homes, clinics, and hotels taking advantage of the many benefits of modular construction such as those from MPH Building Systems.

Although we can also see it in small projects as a suitable and timely solution for the construction of single-family houses and apartments or the renovation of houses, bathrooms, kitchens, etc.

There are strong players in the market that take modular construction to a level of excellence, such as Hydrodiseño, who have been leaders in prefabricated modules for more than a decade.

Keep reading to learn about the news and trends in this industry, the benefits, and characteristics that make modular construction, and using prefabricated modules, a desirable and relevant alternative in both large and small projects.

What is modular construction?

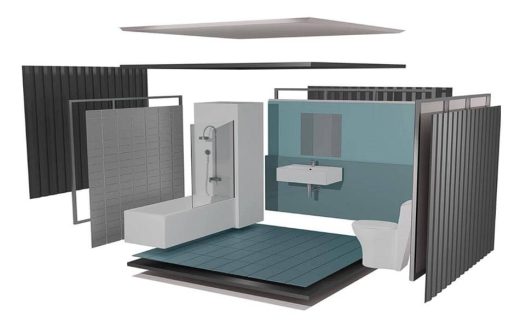

Modular construction is carried out off-site, in the factory, so the prefabricated modules are then transported to the site where they will be assembled (land, lot, or plot).

It can be used for full projects such as the construction of a house or apartment and even in complex large facilities such as hospitals, hotels, and residences.

Benefits of modular construction

The following are some of the benefits of modular construction over traditional in-situ construction:

Increased control and compliance with stipulated deadlines

Unlike traditional on-site construction, prefabricated module construction avoids delays caused by weather, delivery of materials, availability of labour, etc.

Reduced environmental impact

It has a lower environmental impact, as it reduces pollution by making efficient use of water, materials, and energy.

Cost and time savings

It is estimated to deliver cost savings of up to 40% over traditional construction, and it is typically completed 30%-50% faster than projects using conventional in-situ construction.

High-quality construction

Two reasons currently justify the higher quality of modular buildings compared to traditional construction. On the one hand, there is a lower risk of defects since they are executed in environments with controlled conditions.

On the other hand, today’s prefabricated modules use high-quality materials for their construction, guaranteeing both the quality and durability of the finished product.

Design flexibility and increased customization

Reputable companies that manufacture prefabricated modules use technology such as 3D modelling that allows high flexibility of customization and design, as well as better use of space.

Safety at the construction site

Last but not least, modular manufacturing reduces the risk of accidents. This is because it makes operations management easier and creates safe working environments.

What are the materials used for the construction of prefabricated modules?

Three main types of materials are used in the construction of prefabricated modules: concrete, wood, and steel. However, other materials can also be used according to the characteristics and requirements of the project.

Also, hybrid approaches are generally developed in which combinations of two or more types of materials are used.

What is the most suitable material for the construction of prefabricated modules?

First of all, to answer this question several factors such as the type of structure required, its maintenance, climatic conditions, and intended use, as well as the style and design that were chosen, must be considered.

With this in mind, we can say that concrete is usually used for the structural reinforcement of precast modules mainly due to its durability and strength.

Wood is commonly used in diverse elements such as frames, beams, and panels, thanks to its malleability and lightness.

While steel modules are often used, in combination with concrete and wood, in the construction of commercial and industrial buildings. This is mainly due to their ability to adapt to different situations and requirements.

Costs of prefabricated modules

Regarding the costs related to the construction of prefabricated modules, several factors must be considered, such as the materials used, the characteristics of the building or structure to be built, and the conditions of the land where it will be located. So, for example, the prefabricated bathroom pod prices in the UK won’t be the same as in Spain or the United States.

However, as we already mentioned, the cost-quality ratio is usually more beneficial than that of traditional construction. Especially when it comes to large-scale projects. This is especially true for large-scale projects, where significant cost reductions can be achieved through economies of scale.

Prefabricated modular bathrooms and kitchens

Within modular construction, the development of projects that include prefabricated modular bathrooms and kitchens is increasingly used as a way to reduce construction times and associated costs, both in large-scale projects and in single-family or private projects.

Prefabricated kitchens and bathrooms can be installed in new buildings or in buildings that are being renovated or expanded. They are widely used, for example, in hotels, hospitals, clinics, and student residences.

A fundamental advantage is that they can be precisely adapted to the dimensions and characteristics of the available spaces, whether these are large surfaces or small locations.

Modular construction: Is it a good alternative to traditional construction?

While prefabricated modules and, modular construction in general, were initially seen as an “alternative” and “lower quality” option for the construction of temporary buildings, today this has changed radically.

Factors such as the greater regulatory and normative requirements for this type of building, the need for more precise control over modern projects, and the specialization of the elements that make up a building, along with technological advances, have allowed the advance of modular construction, improving the quality of the final product.

As you have seen, modular construction offers several advantages over traditional on-site construction, and it can be used for both individual and large-scale projects.

Comments on this guide to Prefabricated modules and modular construction article are welcome.

Bathrooms Articles

Bathrooms Posts

Give your bathroom a whole new look

photo : Sidekix Media on Unsplash

Spoil your bathroom with stylish tiles

4 bathroom upgrade ideas to improve property value

Building Articles

Comments / photos for the Prefabricated modules and modular construction advice page welcome