How industrial spray machines breathe life into buildings guide, Rapid application spraying systems, Nozzle type advice

How Industrial Spray Machines Breathe New Life Into Buildings

26 December 2023

Spraying can take hours or even days to complete, but industrial spray systems help shorten that process while producing higher-quality and more consistent results. Application systems typically involve a spray gun іn conjunction with handling equipment for rapid application.

Pulling the trigger releases liquid from the gun into compressed air, mixing together to create an atomized paint pattern. The quality and consistency of this paint can be controlled by choosing an appropriate nozzle type for your gun.

The Spray Gun

Spray guns are tools used to transform liquid feedstock into a fine mist and spray it onto substrate. This process, known as atomization, can be carried out using different styles of guns.

Conventional air spray guns use 0.2 to 0.3 MPa (30-40 psi) of high-pressure compressed air for effective atomization and transfer efficiency, but this often wastes over 60% of coating as well as creating overspray pollution.

HVLP (High Volume Low Pressure) equipment allows you to reduce waste and overspray pollution and increase transfer efficiency by lowering air pressure to as little as 10 psi, creating better atomization of paint with reduced spatter and spatter-offsprays.

Codinter offers only top quality HVLP spray equipment and other industrial finishing products at the most competitive market price. However, it’s essential that any equipment purchased meets the specific needs of your company’s operations; otherwise it could result in poor return on investment. That is why we always advise trying out a product before making your final decision to purchase.

The Industrial Spray Machine

Industrial spraying equipment can handle various liquid applications, from paints and stains to primers and sealants and adhesives. Furthermore, this equipment allows businesses to achieve high-quality finishes quickly while cutting down on touch-ups and reprays; saving companies both time and money over time.

Safety must always come first when working with industrial spray machines that use flammable chemicals. Such machines should be placed inside an airtight spray booth that fully encloses and is airtight; such booths typically feature a heat exchanger, filter assembly and exhaust fan that can be controlled separately for maximum convenience. In order to avoid contamination issues it is vital that both exhaust and intake filters are regularly cleaned to avoid potential risks of exposure to contaminants.

Spraying products could take hours or days depending on their size. An industrial spray machine can drastically speed up this process and reduce error risk by coating each piece uniformly – helping ensure the finished product meets industry standards without defects or flaws.

The Finishing Touch

Final touches must be added to a project before it can be utilized, and in this instance he brushed on a coat of gloss to his doorknob to complete his efforts.

Spray painting equipment is extremely versatile, enabling it to be applied on a variety of surfaces such as metals, wood, ceramics, stone and clay (glass). Furthermore, it can be used to apply coatings and chemicals like paint, lubricants solvents deicing liquids adhesives.

Graco provides comprehensive industrial spray packages, providing manufacturers with all of the tools needed for success on any given task. These systems include pumps, mounting hardware, hoses and various spray guns (air spray, air-assisted and airless) designed specifically to meet these requirements.

An increasing global population and rapid economic development have led to an unprecedented surge in construction project demand, driving rapid expansion in the global spray painting machine market. Key players in this sector have focused on sustainable product development to expand sales and broaden their market footprint. They have introduced advanced replacement parts and complete systems for industrial sprayer assembles which improve material regulation to provide precise application of paint, powder, chemicals or liquids on products surface with quality finishes resulting in reduced repainting costs and other related expenses for manufacturers.

Comments on this guide to How industrial spray machines breathe life into buildings article are welcome.

Home Insulation

Building Wall Insulation Posts

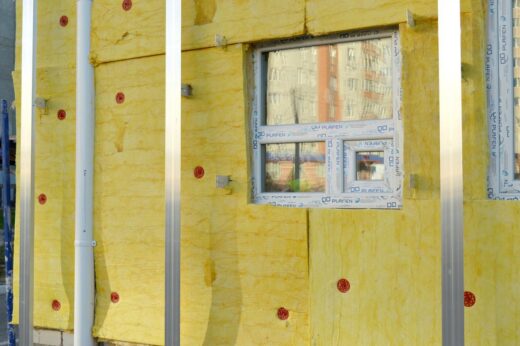

Things to check while selecting commercial insulation

Benefits of External Wall Insulation

Cold-proof your home for winter

Reduce home heating costs with spray foam insulation

Building

Residential Architecture Articles

Comments / photos for the How industrial spray machines breathe life into buildings advice page welcome