Battery-powered grease guns guide, Building machine lubrication, Maintenance product

Battery-powered grease guns lubrication

30 September 2024

The evolution of machine lubrication : introducing battery-powered grease guns

Battery-powered grease guns simplify machine lubrication by offering a more efficient and user-friendly alternative to traditional manual grease guns. These modern tools have revolutionized the way industrial maintenance professionals approach lubrication tasks. By combining the power of rechargeable batteries with the functionality of a grease gun, these devices provide a convenient and effective solution for keeping machinery well-lubricated.

The introduction of battery-powered grease guns has addressed many of the challenges associated with manual lubrication, such as user fatigue and inconsistent application. These tools are designed to handle various types of lubricants, including calcium, aluminum, and lithium-based greases, making them versatile for different industrial applications.

Enhancing efficiency and safety in industrial maintenance

Battery-powered grease guns have transformed maintenance practices, leading to substantial improvements in workplace efficiency and safety standards. These tools enable maintenance technicians to complete lubrication tasks up to 75% faster than with manual grease guns. This increased speed not only boosts productivity but also allows for more frequent and thorough lubrication of machinery, potentially extending equipment lifespan and reducing downtime.

One of the key advantages of battery-powered grease guns is the reduction in user fatigue. Manual grease guns often cause hand strain and discomfort, which can lead to inaccuracies in grease application and slower work rates. By contrast, battery-powered versions minimize physical strain, allowing technicians to work more comfortably and accurately for extended periods.

Safety is another crucial benefit of these tools. The ability to operate with one hand enhances stability and control, reducing the risk of accidents or injuries during the lubrication process. Additionally, the consistent pressure provided by these tools ensures a more precise application of lubricant, minimizing the chances of over- or under-greasing, which can both lead to equipment failures.

Best practices for using and maintaining battery-powered grease guns

To ensure optimal performance and longevity of these tools, proper use and maintenance are essential. Regular cleaning after each use prevents contamination and blockages, maintaining the tool’s efficiency over time. Users should also conduct routine inspections to identify any potential issues before they escalate into more serious problems.

Safety should always be a priority when handling these tools. It’s crucial to disconnect the battery pack before changing accessories or unscrewing the grease cylinder. When not in use, store the battery pack away from metal objects to prevent accidental connections between terminals.

Proper training is vital for anyone using a battery-powered grease gun. This ensures that operators understand how to use the tool effectively and safely. Always follow the manufacturer’s instructions, as different models may have specific requirements or features.

By adhering to these best practices, maintenance professionals can maximize the benefits of these products, ensuring consistent performance and extending the tool’s lifespan. This attention to proper use and maintenance ultimately contributes to more efficient and cost-effective industrial operations.

Innovations and future developments in lubrication technology

The field of lubrication technology continues to evolve, with ongoing innovations enhancing the capabilities of these products. Recent advancements include the integration of lithium-ion battery technology, offering longer run times and faster charging cycles. Some manufacturers are also incorporating smart technologies, such as built-in sensors and Bluetooth connectivity, allowing for more precise control and monitoring of lubrication processes. Take a look at this page on the https://ancotechlub.com website.

Ergonomics and ease of use remain key focus areas, with designers working on lightweight materials and intuitive controls to improve user experience. As the industry moves forward, we can expect to see even more advanced features and improved performance in battery-powered grease guns. To stay informed about cutting-edge lubrication technology, professionals often turn to specialized providers like ancotechlub for comprehensive solutions and guidance.

Comments on this guide to introducing machine lubrication article are welcome.

Home Articles

Residential Architecture

Woodworking

Woodworking Posts

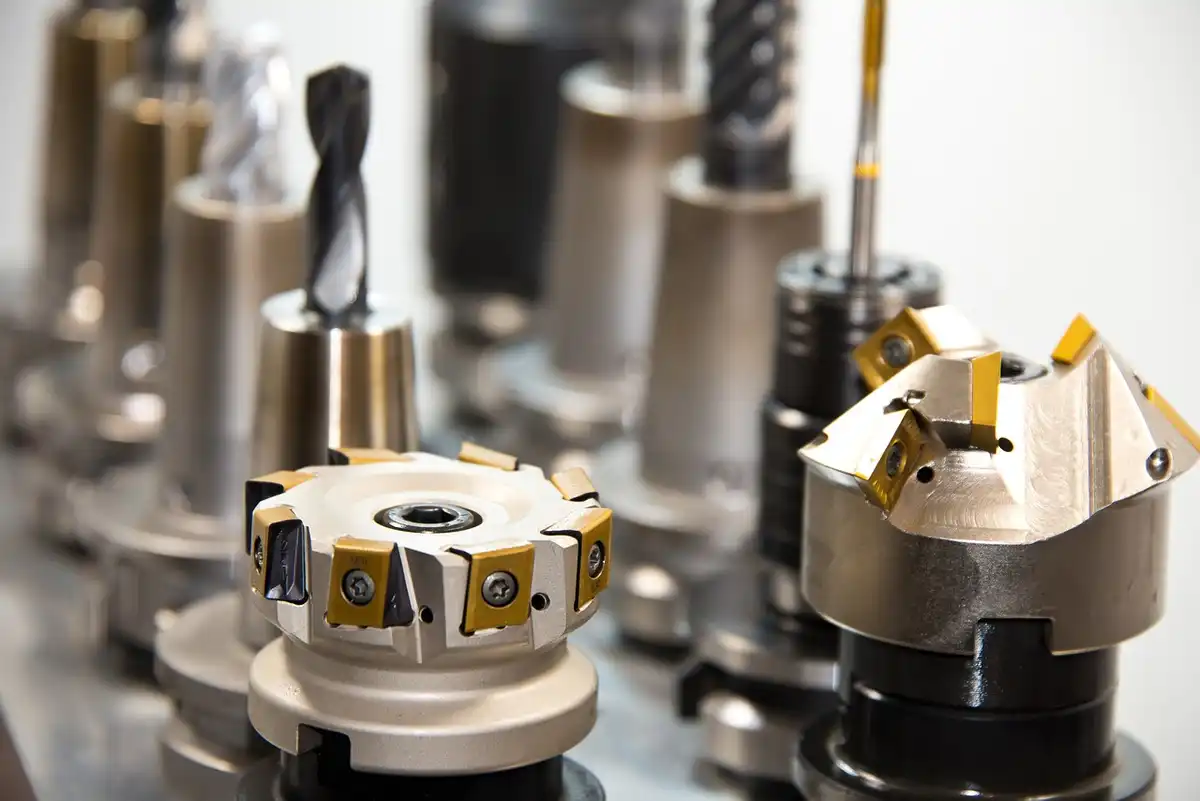

Guide to CNC Machining and its purposes

Excavator rock saws for building sites

Comments / photos for the Battery-powered grease guns: machine lubrication advice page welcome.