Mastering precise woodcuts with horizontal band saw advice, Woodwork tool tips, Property guide

Mastering Precise Woodcuts With A Horizontal Band Saw

24 April 2024

The beauty of woodworking is in its ability to turn plain lumber into exquisite and useful objects. However, for tasks that demand high precision like making heirloom furniture or sculpture, making a perfectly straight, curved, or mitered cut can seem like something you can never accomplish.

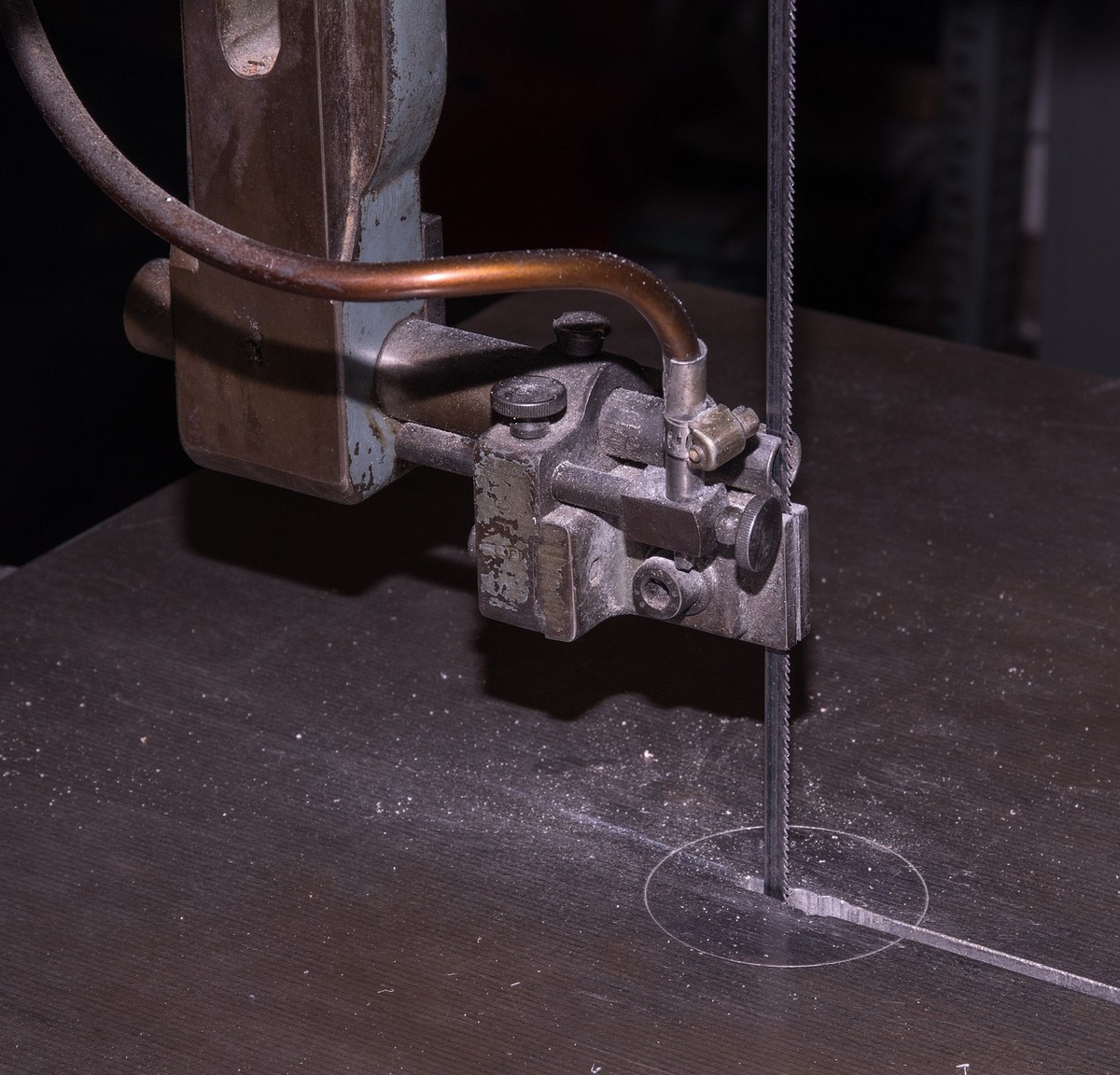

However, a vertical band saw has become a necessity for many woodshops, but the nature of its design is not a big assistance for special woodworking tasks. Set the tread plain as the horizontal band saws, it is a professional tool for those woodworkers in need of the best performance control and accuracy in their work.

A World Beyond Vertical: The Advantages of Horizontal Band Saws

Horizontal band saws have their specific applications and they are distinct from their vertical counterparts which provide different solutions. To some degree, the horizontal bandsaw can be compared to a vertical type of saw where the wood is fed through a blade vertically. Instead, it positions the workpiece flat on a table, enabling millers to guide the workpiece along the saw path much more precisely. This translates to several key benefits:

- Increased Cutting Capacity: The horizontal design makes it possible to manage even larger products. Unlike a vertical band saw, which might have its fair share of difficulties with cumbersome pieces, the horizontal table features conveniently allow for a spacey cutting arc, thus enabling one to work with larger, complex pieces.

- Superior Control and Accuracy: Material stability is a necessary condition for making correct cuts. This workpiece setting-up position horizontally allows the user to have control over the feed, enabling unprecedented cutting accuracy.

- Versatility for Specialized Cuts: The horizontal bandsaws shine in cutting tasks that are greater than straight rips. Until recently you had to have a solid lumber thickness for slicing it into veneers, be able to make perfectly matching cuts for curved elements, and achieve perfectly matching miter cuts for joinery projects all of them are now possible with a horizontal band saw.

Demystifying Resawing: How Horizontal Band Saws Excel

Resawing, cutting thick lumber into thinner stripes, is the basis of woodworking. Horizontal band saws reign supreme in this domain due to several factors:

- Precise Blade Control: The horizontal design solves the wandering of the blades, a frequent problem of vertical band saws which gives access to good control over the cut, resulting in resawn boards of consistent thickness.

- Reduced Waste: Horizontal Band saws usually use thinner blades than vertical saws. It is therefore associated with a kerf (the width of material removed by the blade) narrowing during the cut, thus there is lesser wastage and high yield.

- Efficient Cutting: Slicing a thick lumber on a table saw is a time-consuming and strenuous activity. Horizontal bandsaw work at a speed multiple times higher than normal re-sawing mills, hence shortening the processing time and saving you a great number of workshop hours.

Conquering Curves with Confidence

The process of making the perfect arcs and curves might be a difficult task for woodworkers. Horizontal band saws alleviate this challenge by offering unparalleled control over the cutting process:

- Material Stability: The horizontal rotating of the workpiece allows you to glide it along the saw table with little effort and guide the wood directly along the desired curved line.

- Blade Visibility: Unlike vertical band saws the blade might block your view of the cutting line, horizontal design enables you to see the material and the blade unobstructed. In this way, the transportation of any curve patterns is made possible even for the most complex ones.

- Specialized Blade Options: Horizontal band saws usually have a bigger option of blade types compared to vertical band saws. It also has special blades made to cut the right curves and complex projects that make you feel more confident in handling even the most difficult curved cuts.

Beyond Straight and Curved: Mastering Miter Cuts

Accuracy in miter cuts is the key when it comes to joinery projects, as in the example of making a box or a frame. These band saws too are capable of cutting round stock materials. Through the use of a jigsaw with a setup tailpiece or a straightedge, you can obtain miter cuts at the correct degree and effortlessly undertake the woodworking project you had in mind.

Optimizing Your Horizontal Band Saw for Woodworking Success

To get the most out of your horizontal band saw and achieve master precise woodcuts, consider these practical tips:

- Choosing the Right Blade: Pick the blade with a suitable tooth count for the material you want to cut. Taking the example, blades with a small tooth count are best suitable for making precise cuts of hardwoods while blades with a higher count are of good use when ripping is being done from thicker timbers.

- Sharpen and Maintain Blades: Routine sharpening of blades promotes clean cutting as well as prevents blade deflection, which can disturb accuracy. Invest in a quality blade sharpening tool or take advantage of professional service providers that sharpen blades if you want to utilize your knives for the long term.

- Secure Your Workpiece: It is important to use clamps or fixtures to hold the wood securely against the saw table at all times. This helps to avoid fluke cutting during cutting, thereby guaranteeing the necessary accuracy of the cuts and the low risk of injury.

- Practice Safe Operation: Get yourself acquainted with the proper safety measures for your model of horizontal band saw. Anytime, you should wear necessary safety gear like eye protection, earplugs, and hand protection whenever you are operating the saw.

Conclusion

For woodworkers looking to excel in their skill and achieve the sharpest woodcuts, a horizontal band saw can be the ultimate asset to your workshop. The tool’s capability to tackle heavier lumber stock, precise control, and accuracy, as well as specialty tasks such as resawing, template curving, and miters, would make you approach every woodworking project with renewed confidence.

Whether you’re an amateur or an expert woodworker, a horizontal band saw will be a useful tool to add to your creative arsenal. As a result, buy a band saw, accept in your art that precision is invited, and you will see your woodworking skills fling to newer heights more than ever before.

Comments on this guide to Mastering precise woodcuts with horizontal band saw article are welcome.

Saws

Construction Saw Posts

Home remodelling Need a reciprocating saw

Excavator rock saws for building sites

Architecture Articles

Comments / photos for the Mastering precise woodcuts with horizontal band saw help guide page welcome