5 industrial chiller maintenance tips, Building chilling system guide, Online condenser tube advice

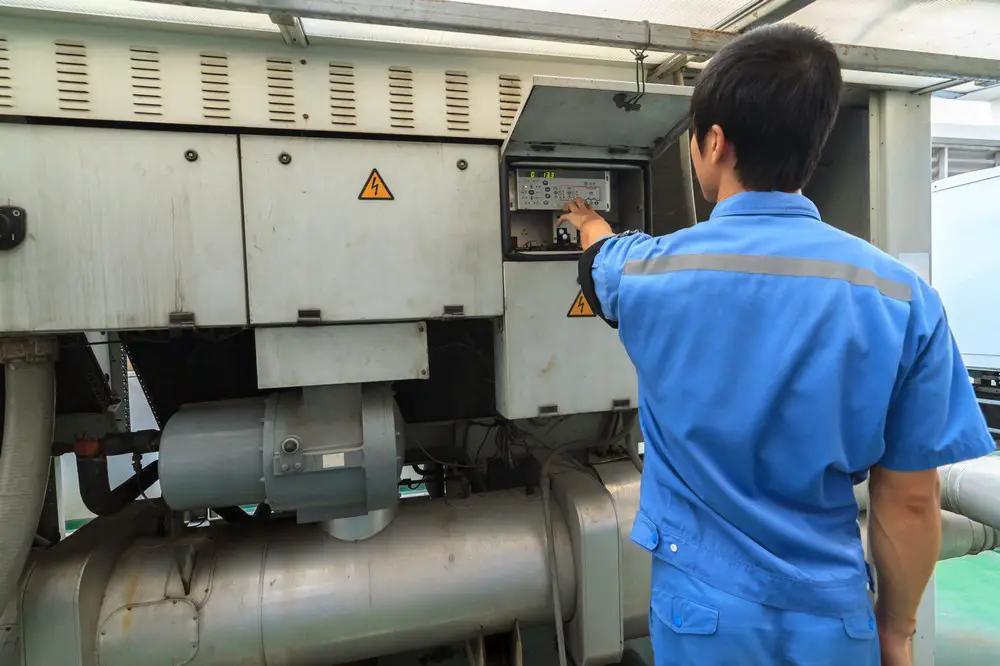

5 Industrial Chiller Maintenance Tips

3 May 2021

Comfort is king and without a proper chilling system, that comfort isn’t coming. So that system is there but it isn’t taken care of, there are fees upwards of $140 an hour or more to take care of it.

Something could have prevented that, regular industrial chiller maintenance. There are steps to take for regular chiller maintenance that can prevent potential damage and keep a system running smoothly.

5 Industrial Chiller Maintenance Advice

- Keeping Tubes Clean

Over time there can be a build-up of contaminants like; mud, scale, algae, in the condenser tubes. These materials can increase thermal resistance and reduce the performance of the unit.

This heat transfer efficiency concern is one of the biggest factors upon the overall performance of an industrial chiller, so it should be at the top of the chiller maintenance list.

Condenser tubes should have a scrubbing at least annually if not sooner to prevent these issues.

- Treating Water

By treating the water that enters the chiller system properly it will prevent the build-up of scale, corrosion, and any other biological growth.

If these things were to occur it would lead to decreased piping and tube effectiveness as well as less effective heat transfer. Inspect and clean any chilled water loops at least once a year.

- Maintaining Refrigerant Charge

The level of cooling a chiller system provides is directly related to the amount of refrigerant that gets moved through the compressor. If the refrigerant charge is low the compressor will be overworked for less cooling.

Be sure to check for refrigerant leaks as well as any air or moisture that may be getting into the system. All of these will lower the efficiency of the system and make it less reliable.

- Analyzing Compressor Oil

This oil does not need to be replaced unless indicated such, as such lubrication oil should be sent for “spectrometric analysis” each year to make sure that is not needed.

- Motor Operation

All motors and starters need to be in proper operation for the chiller system to be totally efficient. To help make sure that all sensor calibrations are accurate and drive motors are inspected for refrigerant leaks.

Besides, make sure to clean all air vents regularly.

Other Care Points for the Industrial Chiller

Another essential maintenance tip that goes beyond anything mechanical is keeping a proper log. Having a log means you have records of operating conditions.

You can keep continual watch over; temperature, fluid levels, pressure, and any other important factors and generate trend reports.

There is no questioning that even the most well cared for chiller system is loud. If there is the need for sound dampening read on here about solutions.

Most commonly this issue is addressed with acoustic blankets and metal paneling.

Learning to Chill Out With Proper Care

Keeping cool and saving money. What’s more appealing?

By following these tips you will be sure to end up with those results. Regular maintenance on your industrial chiller will prevent further costs and will keep things cool!

You’ve made it here with us, so surely it’s been helpful. Be sure to come back and enjoy some more of the material we have curated on the blog soon.

Comments on this 5 Industrial Chiller Maintenance Tips article are welcome.

Air Conditioners

Air Conditioners Posts

6 reasons why ducted air conditioning installation are best

AC repair Easton, PA: home air conditioning in Pennsylvania

AC Replacement and Installation in Lexington KY

Building

Architecture Articles

Comments / photos for the 5 Industrial Chiller Maintenance Tips page welcome